Top 7 Benefits of Regular UPS Maintenance for Offices & Data Centers

Table of Contents

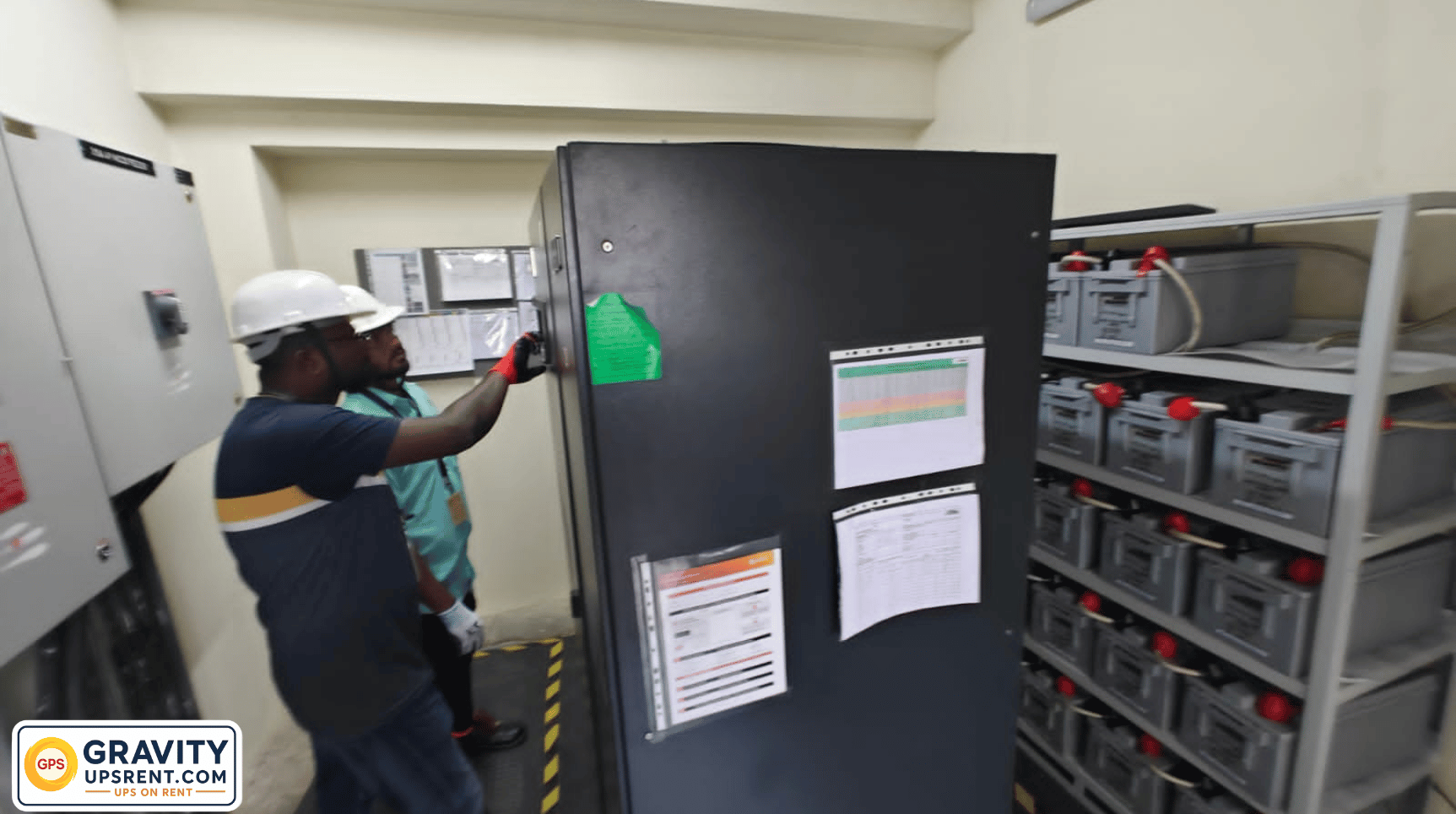

Uninterruptible Power Supply (UPS) systems are the last line of defense between your critical loads and the instability of the electrical grid. Yet, many outages are not caused by sudden component failures—they’re the result of gradually deteriorating batteries, dust-choked fans, obsolete firmware, or skipped health checks. In this guide, we show how disciplined preventive maintenance and an Annual Maintenance Contract (AMC) turn your UPS from a reactive cost center into a proactive resilience engine for offices and data centers.

Introduction: Why Regular UPS Maintenance Matters

Every minute of downtime carries a measurable price: lost transactions, angry customers, SLA penalties, and recovery overtime. Regular maintenance cuts that risk by keeping rectifiers, inverters, and batteries in a known-good state and by catching anomalies before they snowball into failures. For most organizations, the biggest win isn’t just avoiding outages—it’s confidence. With a structured program in place, IT teams can plan work, schedule upgrades, and scale capacity without firefighting.

Looking for a ready-made framework you can adopt quickly? Explore our UPS AMC Services to see how a contract formalizes cadence, scope, and SLAs while keeping costs predictable.

Benefits: The Top 7 You Shouldn’t Ignore

- Higher Uptime: Scheduled inspections and test runs reduce surprise failures, protecting servers, storage, and network gear.

- Battery Health & Runtime Certainty: Capacity checks, IR testing, and replacement planning ensure the backup time on paper matches reality.

- Lower Total Cost of Ownership (TCO): Planned parts and labor beat emergency call-outs, rush spares, and collateral damage costs.

- Safety & Compliance: Proper torqueing, earthing checks, and chemical handling reduce hazards and audit findings.

- Performance & Efficiency: Firmware updates, fan cleaning, and thermal management keep THD low and efficiency high.

- Actionable Insights: Trend reports highlight hot spots, load imbalances, and upcoming capacity constraints.

- Vendor Accountability: With SLAs, response times and spare inventories are contractual, not “best effort.”

What’s Included in a Strong UPS Maintenance Program

Preventive Maintenance

A well-defined PM checklist addresses both electronics and environment. Typical activities include visual inspections, dust removal, thermal scans of busbars and breakers, capacitor and fan health checks, earthing verification, DC link ripple checks, and full-load or simulated-load tests. For battery banks (SMF, tubular, or lithium), we record float voltages, internal resistance, temperature, and intercell connections. The output is a pass/fail summary plus remediation actions prioritized by risk.

Monitoring & Reporting

Continuous monitoring—via SNMP, Modbus, or vendor gateways—provides real-time alarms and historical trends. Monthly or quarterly reports consolidate runtime events, transfer counts, temperature excursions, and battery trends into a one-page executive view and a deeper engineer appendix. The goal is to convert raw signals into maintenance and budget decisions: replace a string now, add ventilation, rebalance phases, or increase capacity before peak season.

Firmware & Spares

Firmware updates close bugs that can cause nuisance trips or misreporting. Meanwhile, a curated spares kit—fans, fuses, boards, and battery interlinks—keeps MTTR low. Your AMC should define which spares are stocked locally, which are fast-shipped, and which require vendor escalation, with clear lead times and ownership.

Process Overview: From Baseline to Continuous Improvement

1) Discovery & Documentation

Collect make, model, kVA, battery type and age, wiring diagrams, breaker maps, and room conditions. Establish single-line diagrams if they’re outdated or missing.

2) Health Baseline

Run non-intrusive tests first: IR scans, harmonic snapshots, event log reviews, and initial battery sampling. This creates a reference to measure improvements.

3) PM Visit & Quick Wins

Execute the PM checklist; fix loose lugs, address airflow obstructions, and correct phase imbalances that elevate heat and reduce inverter efficiency.

4) Battery Audit & Replacement Plan

Identify weak cells, equalize where applicable, and schedule replacements in strings to preserve balance and runtime reliability.

5) Firmware & Controls Update

Update UPS and display controller firmware, validate setpoints, test alarms and SNMP traps to ensure SOC/NOC visibility.

6) Reporting & Governance

Deliver a variance report with a 30/60/90-day action plan: safety first, reliability second, efficiency third. Review in a change-advisory meeting.

Pricing & Comparison Table

Costs vary by kVA, topology (online vs. modular), battery bank size, and SLA. Here’s a simple structure you can adapt:

| Plan | Scope | Best For |

|---|---|---|

| Essential | 2 PM visits/year, safety checks, basic reporting, 8×5 response | Branch offices with low-to-moderate criticality |

| Professional | 4 PM visits/year, battery trending, firmware updates, 12×6 response, spares kit | Corporate HQs and smaller data rooms |

| Enterprise | Quarterly PM + remote monitoring, on-call engineer, 24×7 response, replacement planning | Large data centers and 24/7 operations |

Preventive vs Reactive Maintenance: The TCO & Uptime Logic

Reactive maintenance waits for failure and pays the price: emergency labor, expedited spares, and business disruption. Preventive maintenance applies small, predictable costs to avoid catastrophic ones. Over a three-year horizon, organizations that maintain quarterly PMs and trend batteries typically see fewer transfer events, shorter MTTR, and higher energy efficiency due to clean airflow and updated control logic.

Think of UPS like insurance with dividends: you not only reduce the chance of loss, you also unlock operational wins—simpler audits, easier capacity planning, and the freedom to upgrade during planned windows.

Implementation Guide

Define Criticality

Map loads by business impact—payments, logistics, collaboration suites, production lines. Assign recovery objectives and tier UPS systems accordingly.

Baseline & Remediate

Create your initial health baseline, then tackle quick wins: airflow, cable management, alarm hygiene, and clear labeling. Replace suspect batteries before peak seasons.

Cadence & SLA

Set a cadence—quarterly PM for high criticality, semiannual for moderate—backed by a response SLA and parts availability targets. Define who signs off after each visit.

Governance & Reporting

Run monthly or quarterly review meetings. Track KPIs (alarms closed, thermal anomalies, battery variance, MTTR) and approve remediation budgets with clear ROI.

Supported Brands

APC, Emerson/Vertiv, Delta, Numeric, Socomec, Eaton, Riello, Mitsubishi, Huawei, GE, Schneider/MGE.

FAQ

How often should offices and data centers schedule UPS preventive maintenance?

For high-criticality sites, quarterly PM is the norm; moderate sites can opt for semiannual. Batteries should be trend-tested every visit and load-tested annually.

What’s the single most important battery health indicator?

Internal resistance trends. A rising IR indicates declining capacity even when float voltage looks normal. Use IR plus temperature and visual checks to schedule replacements.

Can maintenance be done without interrupting power?

Yes—many tasks are non-intrusive. For intrusive tests, use bypass paths and maintenance windows. A good AMC will list which actions are hot-work vs. windowed.

Does firmware really impact uptime?

Absolutely. Firmware affects alarm logic, transfer thresholds, and communication stability. Keeping UPS and controller firmware current prevents nuisance trips and misreads.

How do I budget for the next 12–24 months?

Combine your baseline with battery age, IR trends, and environmental factors. Set a quarterly PM budget and earmark a battery reserve based on predicted replacements.

What if my site has mixed brands and ages?

Create a vendor-agnostic inventory, standardize reports, and prioritize upgrades where parts are scarce. Mixed fleets can be managed—governance is the key.

What’s the single most important battery health indicator?

Internal resistance trends. A rising IR indicates declining capacity even when float voltage looks normal. Use IR plus temperature and visual checks to schedule replacements.

Can maintenance be done without interrupting power?

Yes—many tasks are non-intrusive. For intrusive tests, use bypass paths and maintenance windows. A good AMC will list which actions are hot-work vs. windowed.

Does firmware really impact uptime?

Absolutely. Firmware affects alarm logic, transfer thresholds, and communication stability. Keeping UPS and controller firmware current prevents nuisance trips and misreads.

How do I budget for the next 12–24 months?

Combine your baseline with battery age, IR trends, and environmental factors. Set a quarterly PM budget and earmark a battery reserve based on predicted replacements.

What if my site has mixed brands and ages?

Create a vendor-agnostic inventory, standardize reports, and prioritize upgrades where parts are scarce. Mixed fleets can be managed—governance is the key.

Call to Action

Whether you run a regional office or a Tier-III data center, a structured UPS maintenance program pays for itself in avoided incidents and calmer on-call rotations. Speak to our engineers for a quick baseline and tailored AMC options.

Talk to an engineer now

Prefer reading first? Read related UPS AMC resources

Author Info Box

Gravity Power Solution helps Indian businesses design, maintain, and scale mission-critical power systems—covering UPS AMC, rentals, and battery lifecycle services across multiple cities. Our goal: predictable uptime with transparent reporting and measurable ROI.